If I had only kept the camera's rolling post interview, they would have captured the essense of Paul and David's podcast in one line.

David Belman said something to the effect of how his company was simply doing their best for everyone: the customer, the community and the business when Paul's demeanor became serious,

"For all the year's I've been around the home building business, I have to say, Southeast Wisconsin really has an ethical group residential developers. You don't see that in every community."

I chastised him, "Paul, where was that line in the interview?" The room erupted in laugher.

The Cost of Regulation and Why It Matters

Housing affordability isn’t just an economic issue it’s a community issue that affects every Wisconsin family, builder and local government. In the latest episode of Land Development Focus, host Paul Seitz sat down with David Belman, President of Belman Homes, to discuss the rising cost of homebuilding, the impact of regulations, and how builders across our state are working to keep the American Dream within reach.

During his time as President of the Wisconsin Builders Association, Belman helped champion several key pieces of legislation, including the Homeowner Bill of Rights, designed to create more predictability in the development process. He’s seen firsthand how complicated and costly the system can become.

“$87,000 of the cost of a new home comes from local, state, and federal regulations,” Belman explained. “That’s roughly 25% percent of the total cost. There’s a lot of fat we could trim out of that equation.”

It’s an eye-opening statistic that highlights just how much red tape stands between Wisconsin families and an affordable home.

A Builder’s Heart for Community

Beyond the policy conversations, Belman’s work is deeply personal. Through his involvement with Operation Finally Home, his company has built and donated six mortgage-free homes to injured veterans and their families — helping them rebuild not just their homes, but their lives.

“These veterans gave so much for us,” Belman said. “To see them move into a brand-new home and start a new chapter there’s nothing more rewarding.”

It’s a reminder that Wisconsin’s builders aren’t just constructing houses they’re building communities.

How R&R Insurance Fits In

At R&R Insurance, we have the privilege of working with many of the homebuilders and land developers driving growth across Southeastern Wisconsin. People like David Bellman who balance innovation, community and integrity every day.

Our team understands the unique risks builders face: navigating complex zoning approvals, managing multi-phase developments, and protecting their projects and people through every step of construction. Through our Construction & Real Estate Practice Group, we help our clients focus on what they do best: creating spaces for Wisconsin families to thrive while we manage the insurance and risk side of their operations.

Moving the Industry Forward

Belman’s story reflects what so many Wisconsin developers are experiencing: a commitment to doing things the right way, even when the process isn’t easy. It’s a fight worth having one that affects affordability, access and the health of our communities.

At R&R, we’re proud to stand alongside the people building Wisconsin’s future.

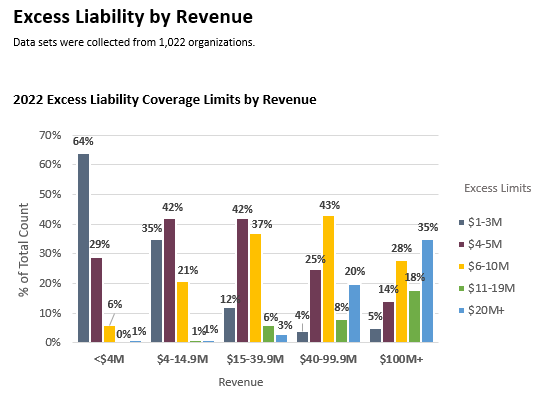

It isn't that surprising to see a direct relationship between revenue and the propensity to purchase greater excess liability limits (umbrella policies). The greater the revenue of a manufacturer, the larger their excess liability limits they tend to purchase.

It isn't that surprising to see a direct relationship between revenue and the propensity to purchase greater excess liability limits (umbrella policies). The greater the revenue of a manufacturer, the larger their excess liability limits they tend to purchase.

It’s a common sight at any industrial park, but five open loading dock doors in front of a moody OSHA inspector could land your company a $63,375 fine!

It’s a common sight at any industrial park, but five open loading dock doors in front of a moody OSHA inspector could land your company a $63,375 fine! OSHA’s new ruling requires edges 4 feet or more in the air to have one of three methods of protection:

OSHA’s new ruling requires edges 4 feet or more in the air to have one of three methods of protection:

Another target of the January 17 language is guarding on fixed ladders. Stationary ladders must have a guard at their opening in order to be complaint. OSHA would frown on the ladder below.

Another target of the January 17 language is guarding on fixed ladders. Stationary ladders must have a guard at their opening in order to be complaint. OSHA would frown on the ladder below. The January rule changes also call for a Walking Worker Surfaces Inspection. These inspections are to be done “on a regular schedule” and “when necessary”. These inspections are to be adequate enough to identify slip, trip, and fall hazards. Employers are mandated by the new rules to have a scheduled WWS inspection and to conduct more when conditions or events occur that warrant an additional check.

The January rule changes also call for a Walking Worker Surfaces Inspection. These inspections are to be done “on a regular schedule” and “when necessary”. These inspections are to be adequate enough to identify slip, trip, and fall hazards. Employers are mandated by the new rules to have a scheduled WWS inspection and to conduct more when conditions or events occur that warrant an additional check.